Why Calibration is Important

According to BIPM, calibration is an operation that, under specified conditions, in a first step, establishes a relation between the quantity values with measurement uncertainties provided by measurement standards and corresponding indications with associated measurement uncertainties and, in a second step, uses this information to establish a relation for obtaining a measurement result from an indication.

What is Calibration?

Basically, Calibration is the process of comparing measurements to a known or guaranteed standard. In order to maintain the accuracy of an instrument the process undergoes is known as Calibration. It is the most common way of configuring an instrument, meter, machine, or device to give an outcome to an example within a satisfactory range. Factors proving to be the cause of inaccuracy need to be minimized or eliminated.

Calibration is what we need for this purpose. Measuring instruments tend to get less reliable over a period of time due to regular mileage. Therefore the instruments need maintenance, and to be tested against a reference standard calibrator so that we know the measurements displayed by the given instrument are completely accurate.

For example, when we calibrate a thermometer, the error of indication or the correction can be determined and adjusted. The thermometer then shows the true temperature in Celsius at specific points on the scale or you can adjust it manually as per the calibration result. So, the final result will be accurate and reliable.

When do we need Calibration?

According to clause 7.1.5.2 Measurement traceability of ISO 9001:2015 [7.6 (a) of ISO 9001:2008], it is the responsibility of industry experts to have calibration records of all monitoring devices including pressure gauges, thermometers, micrometers, vernier scale, voltmeter, pressure gauges & transmitters, deadweight tester, weighing balance, weight scale, measuring cylinder, measuring tape, etc.

Calibration is very important for getting good performance and longevity of your machine which is directly related to the production. That’s why you have to show calibration documents in each and every audit you face (like ISO 9001 audit, ISO/IEC 27001 audit, ISO 14001 audit, ISO 45001 audit, ISO/IEC 17025 audit, ISO/IEC 17020 audit, ISO 22000 audit, ISO 27001 audit, ISO 28001 audit, ISO 50001 audit, ISO 14064 audit, Buyer audits, Technical audit, Compliance audit etc.)

We have discussed what is Calibration, now we shall know what are the possible reasons that require a calibration service.

Types and Benefits of Calibration

Depending on the measuring instrument there are a number of calibrators. Namely, we can say temperature calibrators, electrical calibrators, dead weight testers or pressure calibrators, torque-wrench calibrators, load cell calibrators, calibration repair and maintenance etc. No matter which industry we try to look at, measurement is everything for an effective, efficient, and quality production. If that is the case, quality calibration is a hassle-free way to ensure everything is at its place accordingly and no chance of errors.

To curb the production cost or we can say to increase the profitability, timely and quality calibration status is very important. It increases revenue by deducting unnecessary costs which are usually caused by sample errors.

Calibration activities of the Test and Measuring Instruments save a lot of time. Restarting the entire process due to one small error in measurement equipment consumes much time.

Every day, thousands of products or devices are sent to the market without undergoing any quality check. The responsibility of the industry expert is to ensure that these products are safe for consumption for their clients and are not faulty in any way.

Quality Calibration–boosting efficiency

Quality calibration plays an important role in ensuring that all of the machines are working correctly. Moreover ensures that can be calibrated at any time needed. In terms of safety, the apparatus needs to meet quality assurance and quality control requirements. The quality calibration process ensures that the desired measurements are “traceable” to the internationally defined measurement units.

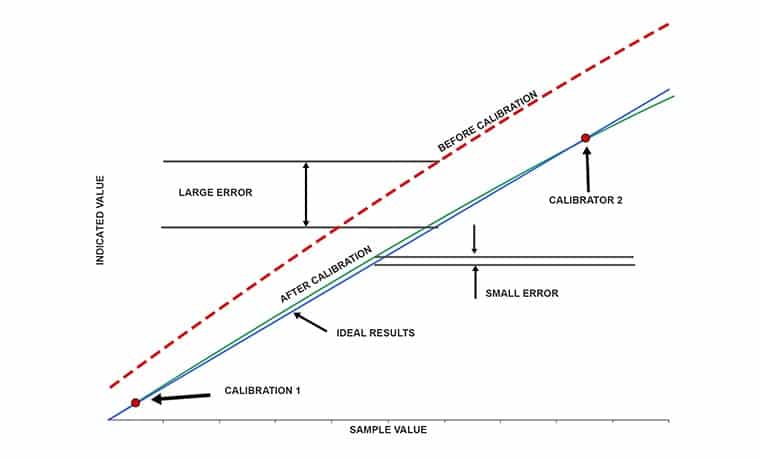

Now let’s look at the figures below.

The figure above shows how an appropriately performed calibration improves the production and performance of a given product or device. The test result of an ideal product would be somewhat near the blue line labeled as “Ideal Results”. Without a calibrated facility, an actual product may produce test results that are different from the sample value and of course with a possible large error.

The red dotted curve shows test results with large errors and situations far away from the ideal result. Whereas after calibrating activity the test apparatus result showed almost zero errors.

This is the reason why we need quality calibration to avoid potential errors. The quality of a calibrator may drop due to many reasons. Namely, using the wrong calibrator values, disregarding calibrator formulation tolerance, disregarding temperature effects, improper sample preparation method, faulty laboratory equipment, etc.