ISO/IEC 17025:2017 | +8801730474822 | tm.qcsbd@gmail.com

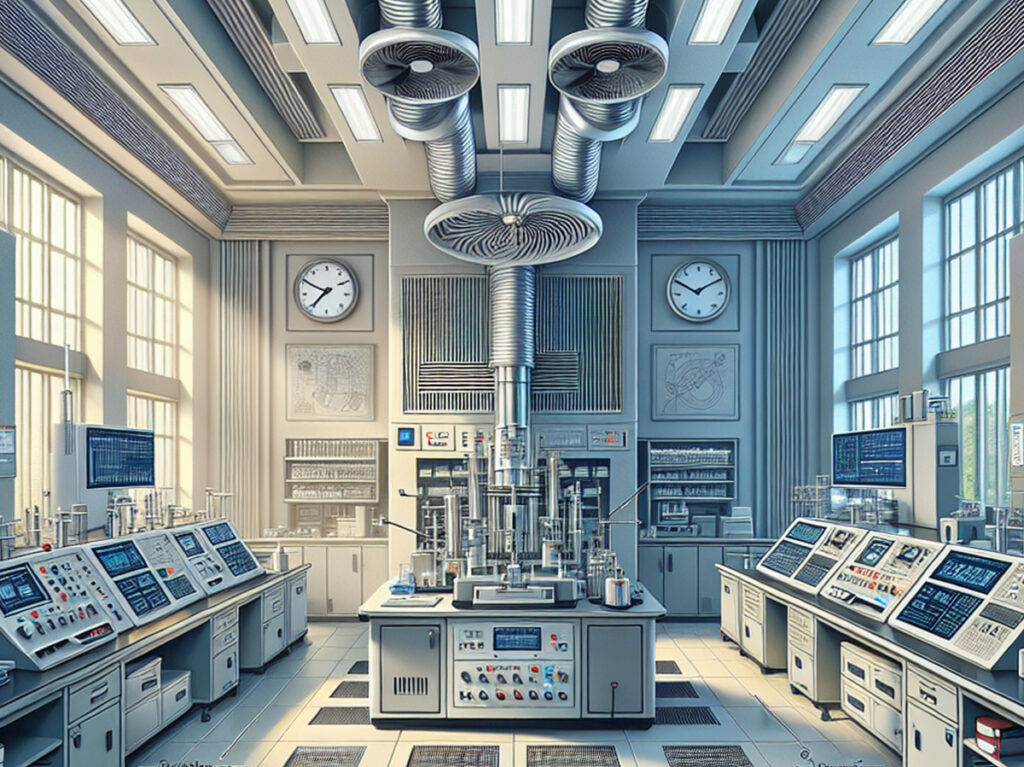

Calibration laboratories play a crucial role in ensuring the accuracy and reliability of measurement instruments. One often overlooked aspect of these facilities is the importance of an efficient ventilation system. In the context of Bangladesh, where environmental conditions can vary, the design and implementation of calibration laboratory ventilation systems become paramount. This article explores the significance of ventilation in calibration laboratories in Bangladesh and discusses key considerations for an effective system.

Importance of Ventilation in Calibration Laboratories

1. Maintaining Instrument Accuracy

A controlled environment is vital for accurate measurements. Ventilation systems help regulate temperature and humidity, ensuring that instruments perform optimally and produce reliable results.

2. Mitigating Contaminants

Calibration laboratories handle sensitive equipment that can be adversely affected by airborne contaminants. Proper ventilation minimizes the risk of dust, pollutants, and chemical vapors, safeguarding the integrity of instruments.

3. Ensuring Personnel Safety

Adequate ventilation not only protects instruments but also safeguards the health and safety of laboratory personnel. It helps dissipate fumes from chemicals used in calibration processes, reducing the risk of exposure.

Challenges in Bangladesh

1. Climate Variability

Bangladesh experiences diverse climates, from hot and humid to cool and dry. Ventilation systems must be adaptable to these variations to maintain a stable environment within the laboratory.

2. Air Quality Concerns

Urban areas in Bangladesh often face air pollution challenges. Calibration laboratories need ventilation systems equipped with robust filtration to counteract the impact of external pollutants on sensitive instruments.

3. Energy Efficiency

Given the rising energy costs and environmental concerns, calibration laboratories in Bangladesh should prioritize energy-efficient ventilation solutions without compromising on performance.

Design Considerations

1. Variable Air Volume (VAV) Systems

Implementing VAV systems allows for dynamic adjustments in airflow, responding to changing laboratory conditions. This flexibility enhances energy efficiency and ensures a consistent environment for calibration activities.

2. Filtration Systems

High-efficiency particulate air (HEPA) and ultra-low penetration air (ULPA) filters are crucial in preventing contaminants from affecting instrument accuracy. Regular maintenance and replacement of filters are essential for sustained performance.

3. Climate Control Features

Laboratories should incorporate climate control features that address the specific environmental challenges in Bangladesh. This may include humidity control, temperature regulation, and air purification technologies.

Regulatory Compliance

Ensuring compliance with national and international standards is imperative for calibration laboratories. Ventilation systems must adhere to relevant guidelines and regulations to guarantee the accuracy and reliability of calibration processes.

Final Words

Calibration laboratories in Bangladesh face unique challenges related to climate, air quality, and energy efficiency. A well-designed and properly implemented ventilation system is indispensable for maintaining instrument accuracy, ensuring personnel safety, and meeting regulatory requirements. By addressing these considerations, calibration laboratories can optimize their operations and contribute to the overall reliability of measurement data in various industries.

Md. Hasan Ibrahim is a Technical Manager at Quality Calibration with extensive experience in the calibration sector since 2015. Holding a Bachelor of Science degree in Mechanical Engineering from Khulna University of Engineering & Technology (KUET), he has received training from various national and international organizations including CSIR-CMERI, QSI, BAB, NML-BSTI, memmert, and X-rite. With expertise in ISO/IEC 17025 assessment, method validation, metrological traceability, and uncertainty, he has successfully completed numerous calibration projects across diverse industries such as pharmaceuticals, food & beverage, oil & gas, textiles & garments, power plants, batteries, chemicals, hospitals & healthcare, and private universities.